Activator

Vulcanization Activator

Vulcanization activators are critical additives that optimize the cross-linking efficiency of diene rubbers during vulcanization. These activators enhance curing speed, increase cross-link density, and improve resistance to reversion, particularly at higher dosages. By working synergistically with accelerators, they elevate the mechanical properties of vulcanized rubber—such as tensile strength, durability, and thermal stability—while enabling precise control over the vulcanization process. Additionally, they reduce waste and toxicity, aligning with sustainable manufacturing practices.

Our ZnO-80 activator exemplifies these benefits, offering robust performance as a high-purity zinc oxide solution. It efficiently replaces or supplements traditional additives like stearic acid without risking surface bloom, ensuring superior dynamic properties and compatibility with a wide range of elastomers. Ideal for automotive, industrial, and construction applications, our activators empower manufacturers to achieve faster production cycles, enhanced product performance, and environmentally optimized processes.

Effect of Vulcanization Activators for Rubber Products

1. Enhances Vulcanization Efficiency and Optimizes Network Structure

Activators accelerate the vulcanization reaction, resulting in a more uniform and optimal crosslink density. This creates a denser and more stable three-dimensional crosslinked network, which forms the foundation for improved mechanical properties.

2. Improves Elasticity and Resilience

By promoting better crosslinking between rubber molecules, activators significantly enhance the elasticity and rebound resilience of the rubber, leading to better fatigue resistance and longer product lifespan.

3. Increases Hardness and Wear Resistance

An appropriate increase in crosslink density raises the hardness of the rubber while also improving wear resistance, making the product suitable for applications requiring high abrasion resistance, such as seals and tires.

4. Enhances Tear Strength and Tensile Strength

Activators facilitate uniform vulcanization, reducing defects and stress concentration points, which improves the rubber’s tear resistance and tensile strength, thereby enhancing overall mechanical robustness.

5. Boosts Heat Resistance and Aging Resistance

By optimizing the vulcanization process, activators help improve the rubber’s heat stability and oxidative aging resistance, enhancing product performance in high-temperature and harsh environments.

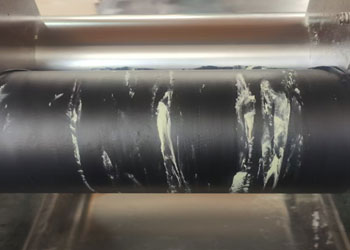

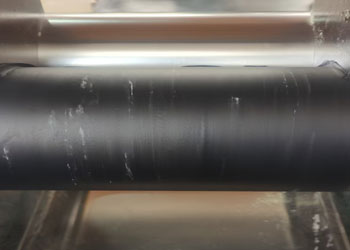

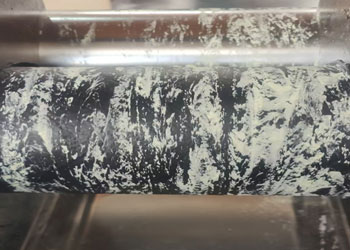

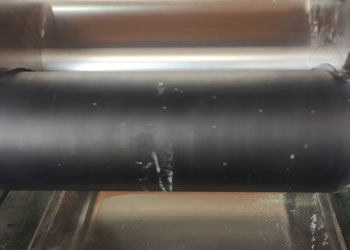

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.