Adhesive System Additive

Additives for Adhesive System

Additives for adhesive systems are specialized components that enhance bonding performance, durability, and processing efficiency in rubber-to-substrate applications. These additives improve adhesion strength, thermal resistance, and compatibility between elastomers and materials like textiles, metals, or plastics, ensuring robust interfacial bonding even under harsh conditions.

Our product range includes Resorcinol (R)-35 and Resorcinol (R)-80, tailored to optimize resin-based adhesive formulations. Resorcinol (R)-35 acts as a key intermediate in rubber-to-fabric bonding systems, promoting crosslinking and enhancing cohesion in high-stress environments. Resorcinol (R)-80, a pre-dispersed masterbatch, ensures uniform resin dispersion and simplified handling, ideal for tire cord adhesion or industrial belt manufacturing.

Ideal for automotive tires, conveyor belts, and composite materials, these additives deliver reliable adhesion, improved flex fatigue resistance, and extended product lifespan. Elevate your adhesive systems with precision-engineered solutions that balance performance, processability, and long-term stability.

Advancements in Additive Technologies for Adhesive Systems

The adhesive industry is continuously evolving, driven by increasing demands for stronger bonds, faster curing, and improved durability. Central to these advancements are innovations in additive technologies—the specialized materials incorporated into adhesive formulations to enhance performance and processing.

1. Enhanced Plasticizers and Flexibilizers

Modern plasticizers offer better compatibility with diverse polymer matrices, providing adhesives with improved flexibility and reduced brittleness. These advancements enable adhesives to perform reliably under varying temperatures and mechanical stresses.

2. Next-Generation Stabilizers

New stabilizers improve resistance to oxidation, UV radiation, and thermal degradation, extending the lifespan of adhesives in harsh environments. These additives help maintain adhesive strength and appearance over time.

3. Eco-Friendly and Bio-Based Additives

Sustainability is a key focus, leading to the development of biodegradable and bio-based additives. These eco-friendly solutions reduce environmental impact without compromising adhesive performance, meeting stricter regulatory standards and customer preferences.

4. Advanced Rheology Modifiers

Innovative rheology modifiers enhance the flow and application properties of adhesives, ensuring smooth and uniform coating. They enable better control during manufacturing and improve the final product’s consistency.

5. Intelligent Curing Agents

Smart curing additives now allow precise control over curing speed and conditions, facilitating faster production cycles and energy savings. These agents can be tailored to specific application requirements, from rapid setting to delayed curing.

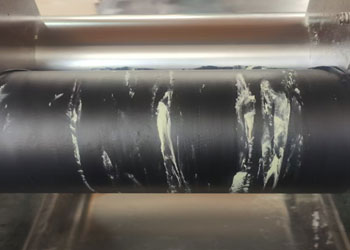

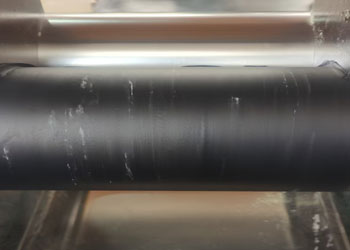

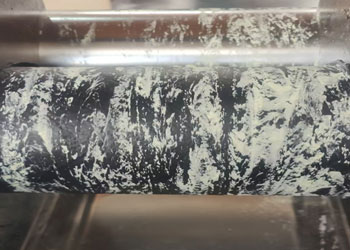

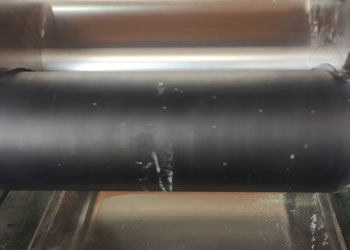

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.