Composite Masterbatch Particles

Composite Masterbatch Particles

Composite masterbatch particles are advanced additive carriers designed to streamline the integration of functional ingredients into polymers and rubber matrices. These particles ensure uniform dispersion of additives—such as stabilizers, colorants, or performance enhancers—while simplifying processing and minimizing dust exposure. By encapsulating active components in a polymer-compatible base, they enhance compatibility, reduce waste, and improve final product consistency.

Our offering is BHFH-80, a high-performance composite masterbatch optimized for applications requiring balanced thermal stability and mechanical reinforcement. Ideal for automotive components, industrial plastics, and specialty rubber goods, BHFH-80 delivers efficient additive delivery, enhanced processing efficiency, and tailored property enhancements.

Is Composite Masterbatch Particles Eco-friendly?

Composite masterbatch particles are increasingly designed to meet the demands of sustainable manufacturing and circular economy principles. These advanced materials contribute to environmental protection and resource efficiency throughout their lifecycle.

Sustainable Raw Materials

Many composite masterbatches use bio-based or renewable raw materials, reducing dependence on fossil resources. Additionally, they comply with strict environmental regulations such as REACH and RoHS, ensuring low toxicity and safety.

Energy-Efficient Production

Manufacturers adopt energy-saving technologies and optimized processes to minimize carbon emissions and waste during production. This results in cleaner manufacturing and a reduced environmental footprint.

Enhanced Product Performance

By improving the durability and functional properties of plastic products, composite masterbatches help extend product life cycles and reduce material waste. Their design also supports better recyclability and material reuse.

Eco-Friendly Packaging and Logistics

Packaging materials are chosen for recyclability or biodegradability, and logistics are optimized to lower transportation emissions, further supporting sustainable practices.

Facilitating Recycling and Reuse

Composite masterbatch particles are engineered for compatibility with recycled plastics, encouraging circular use of materials and reducing reliance on virgin inputs.

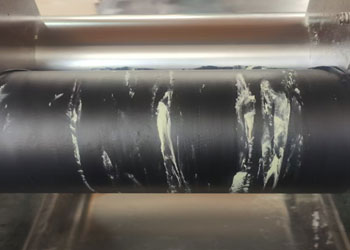

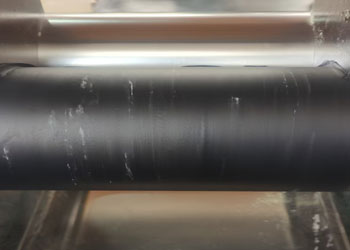

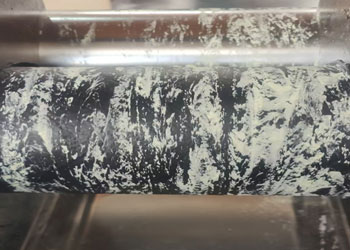

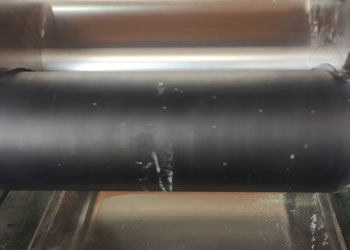

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.