Cross-linking Agent

Cross-linking Agent

Cross-linking agents are essential additives that create chemical bonds between polymer chains, transforming raw materials into robust, three-dimensional networks with enhanced mechanical, thermal, and chemical properties. These agents play a pivotal role in vulcanization, thermoset curing, and the production of high-performance elastomers, coatings, and hydrogels. By controlling crosslink density, they optimize material characteristics such as elasticity, resilience, and resistance to deformation.

Our product line includes TAIC, BH-41-IIR, and TAIC-50, each designed to address unique challenges. TAIC, a triazine-based agent, excels in peroxide-cured systems, delivering exceptional crosslink efficiency and heat resistance for automotive and industrial applications. BH-41-IIR is specifically formulated for butyl rubber, accelerating curing rates while improving mechanical strength and durability. TAIC-50, a pre-dispersed masterbatch, ensures uniform crosslinking in rubber and thermoplastic compounds, simplifying processing and enhancing consistency.

Whether you're developing high-temperature seals, resilient coatings, or advanced hydrogels, our cross-linking agents provide the precision and reliability needed to achieve superior material performance.

Will Cross-linking Agents Affect Material Color, Transparency, or Surface Quality?

The choice of a cross-linking agent plays a critical role not only in achieving desired mechanical properties but also in determining the aesthetic quality of the final product. B2B buyers often ask whether a cross-linking agent can alter a material’s color, transparency, or surface finish. The answer depends on the chemical nature of the agent, the base material, and the processing conditions.

Impact on Color

Some cross-linking agents may generate colored by-products during the curing process, leading to slight yellowing or color shifts. This is particularly common when the agent contains aromatic structures or nitrogen-based compounds that undergo thermal oxidation. Additionally, certain cross-linkers can react with pigments or dyes in the formulation, causing subtle but noticeable color deviations.

Impact on Transparency

Transparency is sensitive to microstructural changes in the polymer. Poor compatibility between the cross-linking agent and the resin may cause phase separation, resulting in light scattering and haze. Over-crosslinking can also create a dense micro-network or microvoids that reduce light transmission, making a previously transparent product appear cloudy.

Impact on Surface Quality

If a cross-linking agent is not fully reacted, unreacted residues can migrate to the surface, creating a hazy, oily, or spotted appearance. Uneven curing may lead to variations in surface hardness, causing texture differences such as ripples or micro-defects. High processing temperatures may also trigger localized scorching, further compromising the finish.

How to Minimize Adverse Effects

To maintain optimal appearance, manufacturers can select highly compatible, light-colored, and thermally stable cross-linking agents. Incorporating antioxidants or UV stabilizers can further protect against discoloration. Careful control of dosage, mixing uniformity, and curing parameters help ensure complete reaction, reducing haze and surface defects.

While cross-linking agents can influence visual and surface properties, these effects can be minimized with the right material selection and process optimization. For applications where aesthetics are as important as performance, choosing a suitable cross-linker and fine-tuning processing conditions is essential.

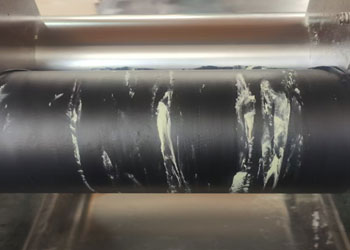

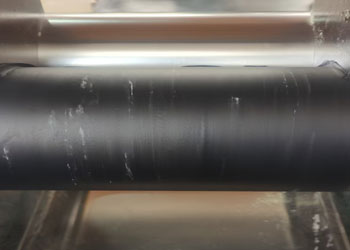

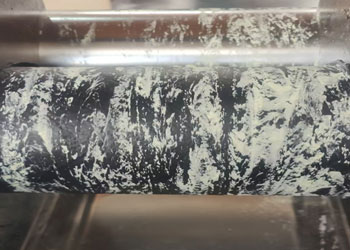

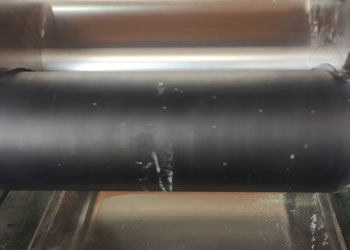

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.