Metal Oxide

Metal Oxide

Metal oxides play a critical role in enhancing the performance of rubber and polymer systems, acting as activators, stabilizers, and reinforcing agents. These inorganic compounds, known for their thermal stability and chemical resistance, improve curing efficiency, mechanical strength, and durability in a wide range of industrial applications.

Our product line includes TiO2-80, a high-performance titanium dioxide-based masterbatch designed to optimize rubber vulcanization and polymer reinforcement. TiO2-80 enhances crosslinking efficiency, improves heat resistance, and provides excellent UV protection, making it ideal for automotive tires, industrial seals, and outdoor polymer products.

By integrating TiO2-80 into your formulations, you can achieve superior material performance, extended product lifespan, and enhanced processing efficiency. Elevate your rubber and polymer systems with metal oxide solutions that deliver reliability, stability, and tailored functionality for demanding applications.

Metal Oxide Particle Characteristics

Particle Size Distribution and Specific Surface Area

The particle size distribution of metal oxides, whether in the nanometer or micrometer range, directly affects their surface reactivity, dispersibility, and functional performance. Smaller particles typically have a larger specific surface area, which can enhance catalytic activity, improve UV shielding, or increase reactivity in chemical processes.

Crystal Structure

The crystal phase of a metal oxide determines many of its physical and chemical properties. For example, in titanium dioxide, the ratio of anatase to rutile phases significantly influences photocatalytic efficiency, optical behavior, and stability. Selecting the right crystal structure is essential for matching the product to its target application.

Particle Morphology

The shape of particles—whether spherical, needle-like, or plate-like—affects packing density, surface contact, and mechanical reinforcement in composites. Spherical particles may offer better flowability and dispersibility, while needle-like or plate-like structures can enhance strength, barrier properties, or functional surface effects.

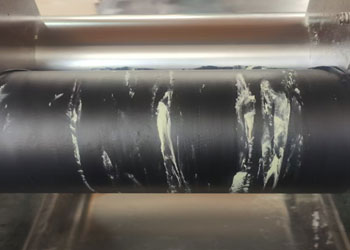

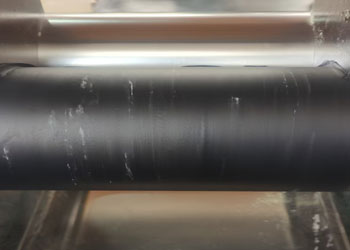

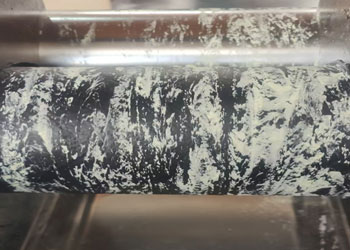

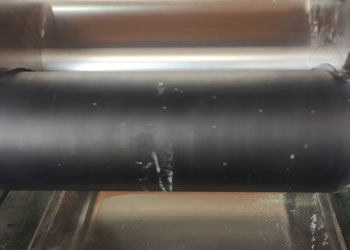

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.