Plasticizing Agent

Synthetic-based Plasticizers

Synthetic-based plasticizers are essential additives that enhance the flexibility, processability, and durability of polymers and rubber compounds. By reducing intermolecular forces, these plasticizers improve material softness, low-temperature performance, and resistance to wear, making them ideal for applications requiring tailored mechanical properties.

Our product line includes DBD-40, a high-performance synthetic plasticizer designed for compatibility with a wide range of elastomers and thermoplastics. DBD-40 ensures uniform dispersion, reduces processing temperatures, and enhances the final product's elasticity and resilience.

The Role of Plasticizers in Extending Product Lifespan

Plasticizers play a critical role in maintaining the flexibility, softness, and mechanical integrity of polymer-based products over time. By reducing the glass transition temperature and improving molecular mobility within the polymer matrix, plasticizers help prevent brittleness, cracking, and premature failure caused by aging, thermal cycling, or environmental exposure.

In long-term applications—such as cables, flooring, automotive interiors, and medical tubing—well-selected plasticizers can significantly slow down performance degradation by resisting migration, minimizing volatility, and maintaining compatibility with the base polymer. This ensures that the product retains its functional and aesthetic properties throughout its intended service life, ultimately reducing replacement costs and improving customer satisfaction.

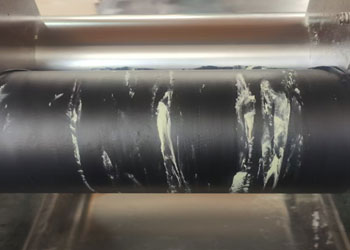

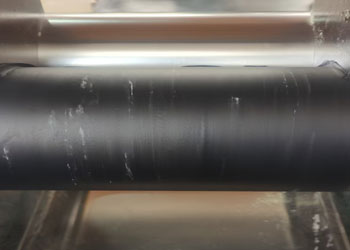

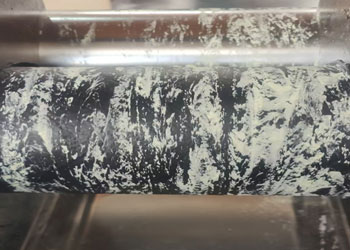

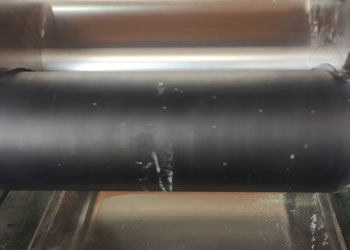

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.