Rubber Plasticizer

Specialty Plasticizers for Rubber

Specialty plasticizers are vital additives that enhance the flexibility, processability, and durability of rubber compounds by reducing intermolecular friction and improving polymer chain mobility. These additives ensure uniform dispersion of fillers, lower processing temperatures, and optimize the final product’s elasticity, low-temperature performance, and resistance to wear.

Our portfolio includes RUBBER PLASTICIZER A, a high-efficiency ester-based solution designed to balance softness and mechanical strength in synthetic and natural rubber formulations, and Protective Wax ML19, a microcrystalline wax that migrates to the rubber surface to form a protective barrier against ozone, UV degradation, and environmental aging.

Ideal for automotive seals, industrial hoses, and construction materials, these plasticizers deliver tailored performance while maintaining compatibility with sulfur-cured and peroxide-cured systems. Elevate your rubber products with enhanced processing efficiency, extended service life, and superior resistance to harsh conditions.

How Plasticizers Reduce the Release of Harmful Volatile Compounds

1. Use of Low-Volatility Raw Materials

Specialty plasticizers are formulated using high molecular weight, low-volatility materials to minimize the emission of volatile organic compounds (VOCs) during processing and vulcanization.

Chemical structure is designed to enhance thermal stability and increase evaporation temperature, thereby reducing the rate of volatilization.

2. Optimized Molecular Structure Design

Plasticizers with moderate polarity and longer molecular chains improve compatibility and bonding with the rubber matrix, which lowers the amount of free, unbound plasticizer that can volatilize.

Functional groups are introduced to strengthen interactions with rubber chains, reducing plasticizer migration and release during processing.

3. Improved Production Process and Formulation Control

Precise dosing of plasticizers avoids excessive use, which can lead to higher emissions of free plasticizer vapors.

Rubber formulations are optimized to enhance the binding efficiency of plasticizers, minimizing the free fraction available for volatilization.

Use of multifunctional or composite plasticizers enhances overall stability and reduces volatility compared to single-component plasticizers.

4. Use of Environmentally Friendly Plasticizers

Adoption of green plasticizers compliant with regulations such as REACH and RoHS ensures low toxicity and low volatility.

Incorporation of bio-based or renewable-resource plasticizers results in volatile emissions that are easier to degrade and environmentally safer.

5. Optimized Processing Conditions

Controlling processing temperatures and times prevents thermal decomposition and volatilization of plasticizers.

Use of closed or well-ventilated equipment minimizes the escape of harmful vapors into the workplace.

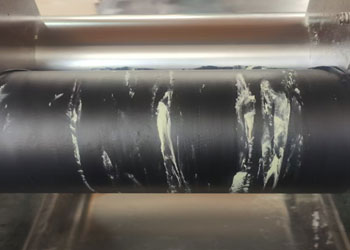

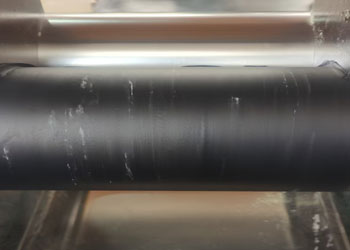

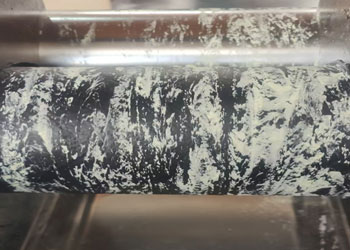

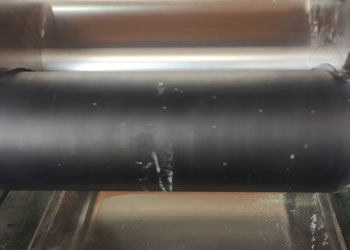

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.