Staple Fiber Reinforcement

Chopped Fiber Reinforcement

Chopped fiber reinforcement enhances the mechanical properties of injection and compression molding compounds across matrices such as thermoset/thermoplastic resins, rubber, and cement. Available in tailored lengths (3–24 mm), these fibers improve strength, stiffness, and dimensional stability in high-performance applications like automotive brakes/clutches and electrical housing components.

Our APM40 chopped fiber is engineered for superior reinforcement efficiency. With optimized fiber length and high bulk density, APM40 ensures consistent dispersion during compounding, minimizing processing challenges while maximizing load-bearing capacity. Compatible with engineering thermoplastics (e.g., PC, Nylon) and high-temperature resins (e.g., PEEK, PEI), it delivers exceptional strength-to-weight and stiffness-to-weight ratios.

APM40 excels in demanding environments, offering seamless integration into pellets, flakes, or custom forms to suit diverse manufacturing needs. Elevate your composites with APM40’s balanced flow characteristics, enhanced processability, and reliable performance in automotive, aerospace, and industrial applications.

Benefits of Using Chopped Fiber Reinforcement in Plastic and Polymer Composites

Chopped fiber reinforcement is widely used in plastic and polymer composites to enhance their mechanical properties and overall performance. These short fibers, typically made from materials like glass, carbon, or aramid, are cut into small lengths and uniformly dispersed within the polymer matrix.

This reinforcement technique offers several key benefits:

1. Improved Mechanical Strength and Stiffness

Adding chopped fibers significantly increases the tensile strength, flexural strength, and stiffness of composites. The fibers act as load-bearing elements that help distribute stress evenly, reducing material deformation under pressure.

2. Enhanced Impact Resistance

Chopped fiber reinforcement improves the toughness of plastic composites, making them more resistant to impact and sudden forces. This property is crucial in automotive, aerospace, and consumer goods applications where durability is essential.

3. Better Dimensional Stability

The fibers help reduce shrinkage and warping during processing and in-service use, maintaining the shape and size of the final product over time and under varying environmental conditions.

4. Cost-Effective Reinforcement

Compared to continuous fiber reinforcements, chopped fibers are easier and less expensive to process. They allow for faster manufacturing cycles and greater design flexibility without sacrificing performance.

5. Improved Thermal Resistance

Certain chopped fibers, like glass and carbon, can enhance the heat resistance of polymer composites, enabling their use in higher temperature environments.

6. Versatility and Ease of Processing

Chopped fiber composites can be molded using standard plastic processing techniques such as injection molding, extrusion, and compression molding, facilitating mass production.

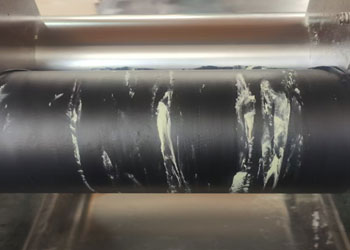

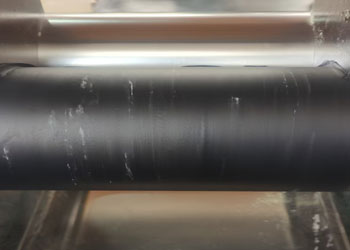

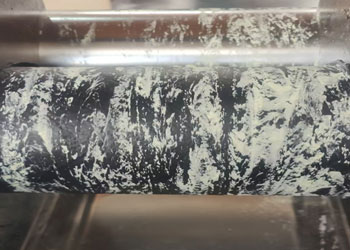

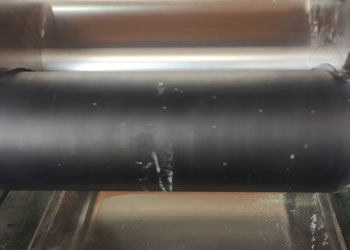

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.