Uniform Agent

Chemical Dispersing Agent

Chemical dispersing/homogenizing agents are critical additives designed to ensure consistent dispersion of fillers, pigments, and functional components within polymer matrices. By eliminating agglomeration and phase separation, these agents enhance material homogeneity, mechanical performance, and processing efficiency while reducing defects in final products.

Our product line includes HA-100 and HA-40, engineered for diverse industrial applications. HA-100 excels in high-temperature processing systems, offering robust stabilization for filled thermoplastics and elastomers. HA-40 is optimized for high-loading formulations, ensuring seamless integration of additives in rubber compounds or masterbatches.

Difference between Wetting Agent and Dispersing Agent

Wetting Agent

A wetting agent reduces the surface tension between a liquid and a solid surface, allowing the liquid to spread more easily and uniformly over that surface. It helps the liquid “wet” the surface better.

Example: In paint, a wetting agent helps the liquid paint spread evenly on a wall.

Dispersing Agent

A dispersing agent helps break up and separate solid particles suspended in a liquid, preventing them from clumping or settling. It stabilizes the suspension by keeping particles evenly dispersed.

Example: In ink or coatings, a dispersing agent prevents pigment particles from aggregating and settling.

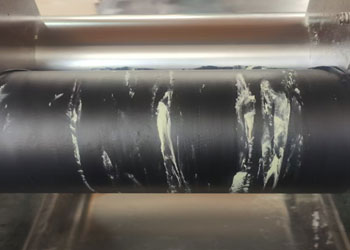

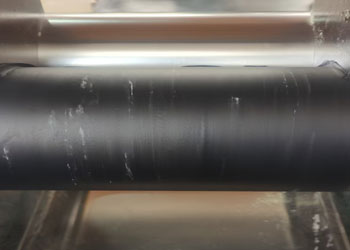

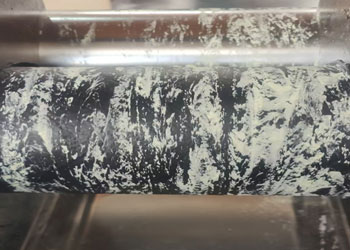

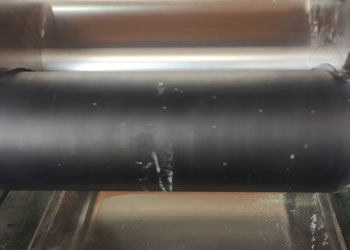

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.