Vulcanization Accelerator Masterbatch

Rubber Accelerator Masterbatch

Rubber accelerator masterbatches, also called pre-dispersed rubber accelerators, are crucial additives in rubber processing, aimed at enhancing the vulcanization process by speeding up the cross-linking reactions between polymer chains. These masterbatches provide precise control over curing speed, efficiency, and the final performance of the product, resulting in improved elasticity, heat resistance, and durability for various rubber applications.

Our selection features specialized formulations designed to meet a wide range of industrial requirements, encompassing key accelerator types such as Thiurams, Thiazoles, Sulfenamides, Dithiocarbamates, Thioureas, Guanidines, Adhesion Agents, and Vulcanizers. Each category presents distinct advantages, from ensuring scorch safety to enhancing adhesion or fine-tuning cure rates and guaranteeing compatibility with different rubber compounds and processing conditions.

Perfect for automotive, industrial, and construction sectors, our vulcanization accelerator masterbatches provide consistent quality, process reliability, and outstanding mechanical properties, enabling manufacturers to efficiently produce high-performance rubber products.

Compatibility and Dispersion of Rubber Accelerator Masterbatch in Different Rubber Systems

A high-quality Rubber Accelerator Masterbatch is tailored to the chemical and physical characteristics of each rubber system by adjusting carrier materials and accelerator combinations.

NR System

- Compatibility: Natural Rubber is a non-polar natural polymer. Rubber Accelerator Masterbatches are typically designed to be highly compatible with non-polar rubber matrices like NR. The active ingredients in the masterbatch can disperse evenly within the NR matrix, ensuring smooth vulcanization.

- Dispersion: NR has good processing characteristics, allowing the masterbatch to disperse thoroughly during mixing. This prevents localized concentration of accelerators, reducing variability in final product performance.

NBR System

- Compatibility: NBR is a polar rubber. Masterbatch formulations often adjust the carrier and dispersing agents to enhance affinity with the polar NBR matrix. Some masterbatches use polar carriers to improve penetration and uniform distribution of accelerators within NBR.

- Dispersion: Due to stricter processing temperatures and mixing conditions for NBR, high-quality masterbatches rapidly break down and release accelerators, ensuring even dispersion. This improves vulcanization efficiency and the finished product’s oil resistance and mechanical properties.

CR System

- Compatibility: CR is a polar rubber containing chlorine atoms, which imposes higher demands on the chemical stability and resistance of accelerators. Superior Rubber Accelerator Masterbatches use specially modified carriers and anti-chlorination technologies to enhance compatibility with CR and prevent accelerator degradation.

- Dispersion: During mixing with CR, the masterbatch must ensure quick release and even distribution of accelerators to avoid localized over-acceleration, which can cause uneven vulcanization and product defects.

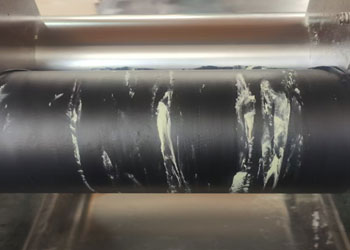

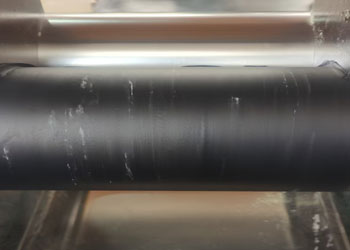

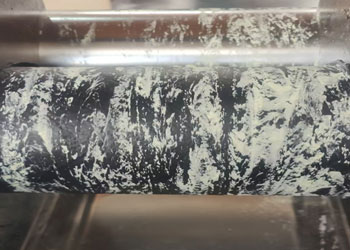

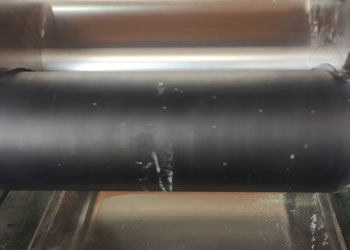

Comparison of roll kneading performance with powder products

| 10 seconds later | 30 seconds later | 60 seconds later | |

| MASTERBATHCES |  |

|

|

| POWDER |  |

|

|

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.

Jiaxing Beihua Polymer Auxiliaries Co., Ltd. / Shanghai Crystal Wells Chemical New Materials Co., Ltd.